Tomato Quality Grading

Learn how you can use hyperspectral imaging for tomato quality grading: Non-destructively, efficiently and in real time.

Learn how you can use hyperspectral imaging for tomato quality grading: Non-destructively, efficiently and in real time.

In the modern agricultural sector, ensuring consistent quality in premium produce is crucial for maintaining customer satisfaction and optimizing market value.

A mid-sized tomato farming operation producing 10,000 tonnes per year sought to improve the accuracy and efficiency of their tomato quality grading process. Their goal was to reduce variability in their premium-grade, sweetest tomatoes while maintaining high throughput at their packing line.

Most existing automated quality grading and sorting systems are designed for handling individual tomatoes at a much larger scale. However, for this premium product, it was essential to grade and package the tomatoes while they remained attached to the truss, as this represents an important consumer preference.

This requirement introduced additional complexity, necessitating an innovative approach to ensure both quality and efficiency in sorting. To address these challenges, the farm implemented an industrial, in-line Hyperspectral Imaging (HSI) solution from HySpex. This application note details the problem, the implemented solution, and the results achieved through this technological advancement.

Manual sorting of tomato trusses presented several challenges:

Visual-to-Taste Inconsistency

While sweet tomatoes of this type will have a deep red colour, not all red tomatoes will actually have a sweet taste. Damage to the plant stem or truss during growth could lead to mature, deep red tomatoes that are less sweet than expected. Manual and visual inspection led to errors in grading.

Destructive Testing Limitations

Traditional lab or sensory tests for sweetness were not feasible on individual trusses due to their destructive and/or time-consuming nature.

Shift Variability

Differences in grading accuracy among graders caused inconsistencies in the final product’s quality.

Lack of Digitization

Manual grading processes lacked objective data collection, making it challenging to analyse quality trends, identify areas for operational improvement, and refine business strategies based on a deeper understanding of product variability.

Figure 1: A compact HSI solution comprising hyperspectral instrumentation, illumination, and real-time quality grading output on an integrated screen. This image is from an early-stage demo setup at the customer site.

To overcome these challenges, the farm adopted an advanced HSI solution from HySpex, capturing hyperspectral data to determine the tomatoes’ Brix value. Brix value measures the sugar content in a liquid solution, expressed as a percentage by weight. This solution enables:

Non-Destructive Sweetness Measurement

The system, mounted above the conveyor belt, as seen in Figure 1, optically scans tomatoes through the skin in real-time without touching or altering them.

Automated Quality Classification

The HSI solution objectively evaluates and documents the sweetness of each tomato, removing subjectivity from the grading process.

Real-Time Data Presentation

Colour coded results are displayed to 2-4 operators on separate screens along the packing line, allowing for effective decision support during high-paced operations.

Enhanced Throughput

The system is designed to handle 40 trusses per minute, which is matching the speeds with which 2-4 trained operators can cut and sort the trusses.

The adoption of in-line HSI technology resulted in several significant advantages:

Higher Consistency in Premium Quality

Non-invasive, timely, and accurate Brix measurements of every, single tomato improved the reliability of premium product classification.

Reduced Quality Give-Away

The improvements in quality grading also resulted in fewer high-quality tomatoes being mistakenly packaged and sold as a lower quality product.

Data-Driven Business Insights

Comprehensive automated data collection and documentation established a strong foundation for the farm to analyse and gain deeper insights into quality variations over time. This allowed them to optimize operations and fine-tune their marketing and business strategies.

Scalability and Future Expansion

The digital grading system provides a foundation for further automation and optimization across the production line.

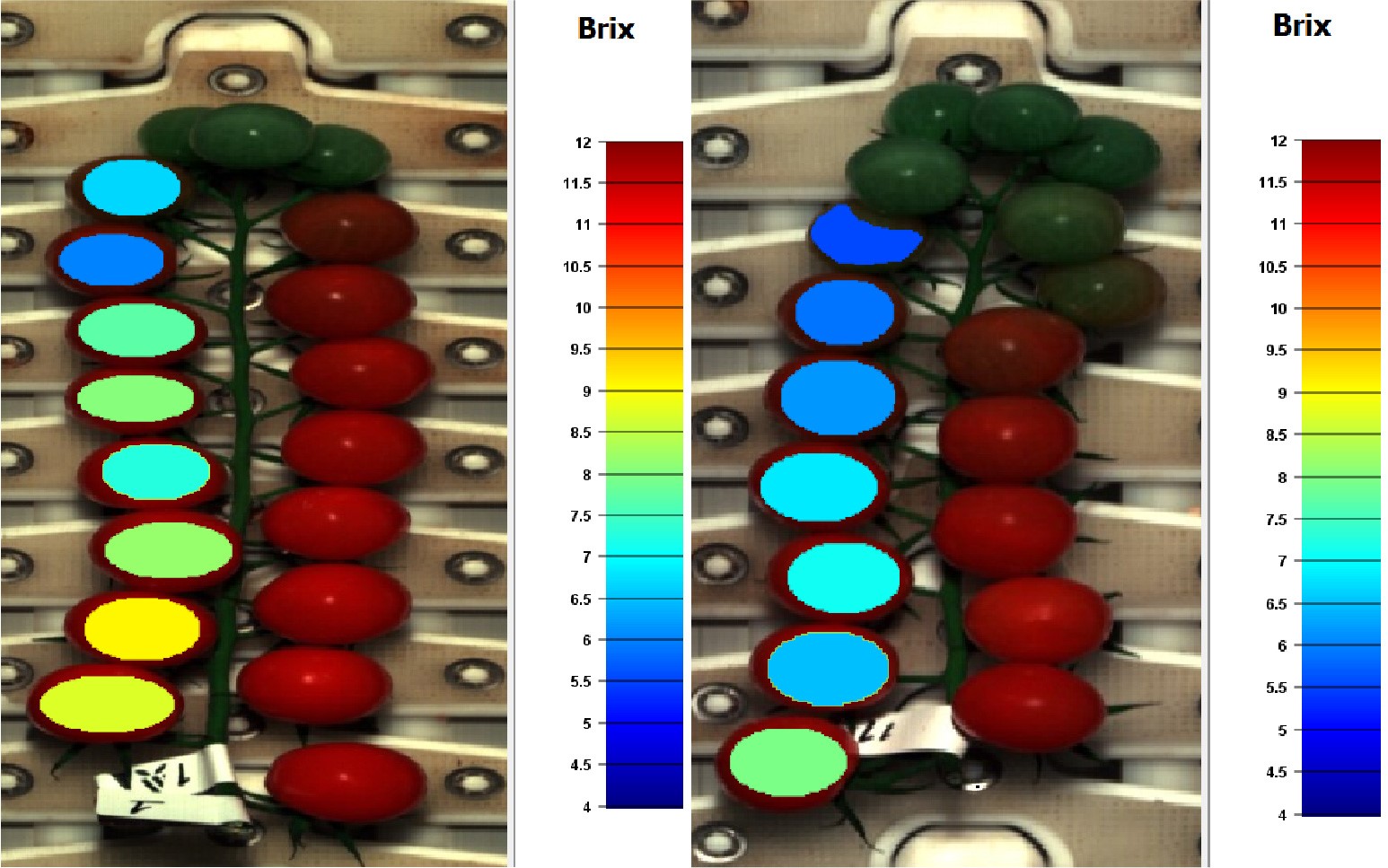

Figure 2: A representative colour visualization of two trusses captured by the hyperspectral camera HySpex Baldur V-1024 N, with predicted sweetness (Brix scale) overlaid on a subset of the tomatoes. Although the truss on the right appears just as red and sweet as the one on the left, its actual sweetness is lower due to an injury to the tomato plant's stem during growth.

Figure 2 illustrates how the HSI solution objectively reveals differences in sweetness that are not always visible to the naked eye. While both trusses appear similarly red, the predicted Brix values indicate a lower sweetness in the truss on the right.

This discrepancy highlights the impact of plant health on fruit quality, as the reduced sweetness is attributed to stem damage sustained during growth. Prior to implementing the HSI solution, tomatoes from such damaged plants often ended up in the premium product, posing a risk of customer dissatisfaction and potential harm to brand reputation.

By integrating a Hyperspectral Imaging solution from HySpex, the farm successfully addressed the limitations of manual tomato grading. This innovation enhanced the accuracy, efficiency, and consistency of their quality grading process, positioning them at the forefront of technological advancements in modern agriculture.

By leveraging real-time, non-invasive quality assessments, they not only improved their premium product line but also gained valuable insights into production variability, paving the way for continued operational excellence and market growth.

Baldur V-1024 N is part of HySpex’s line of industrial hyperspectral cameras, designed to be fast, flexible, robust and repeatable.

It covers the full VNIR spectral range from 400-1000 nm with a 5.5nm sampling, allowing measurements of both colour and the third overtone range of the NIR spectrum. When combined with an optimized illumination setup, this allows for Brix-measurements deep into the individual tomatoes.

Our cameras are designed and built to minimize image distortions like keystone and smile, ensuring reliable spectroscopic measurements across the entire image, even at the individual pixel level. They are also engineered for robustness and repeatability, making it easy to transfer analysis models between systems and scale up operations with confidence.

As a part of HySpex’s dedication to innovation and quality, all of our cameras adhere to the IEEE (Institute of Electrical and Electronics Engineers) standard for hyperspectral imagers. This ensures that our customers can know with certainty that products purchased from us can meet their target specifications before buying one of our systems.

HySpex is an industry-leading brand for hyperspectral imaging systems used across a wide range of industries and research institutions. Our turn-key solutions help improve automation and digitalization to solve problems across a broad range of sectors and application areas.

Fill out a contact form or send us an email to discuss your application and requirements with our specialists.

Methane Detection

Asbestos

Hyperspectral Imaging for Ore Distinction

Hyperspectral Analysis of Powder Mixtures

Pharmaceuticals

Plastic Sorting

Explosives

Paper Recycling

Rare Earth Elements

Coating thickness

Monument Preservation

Cocoa Beans